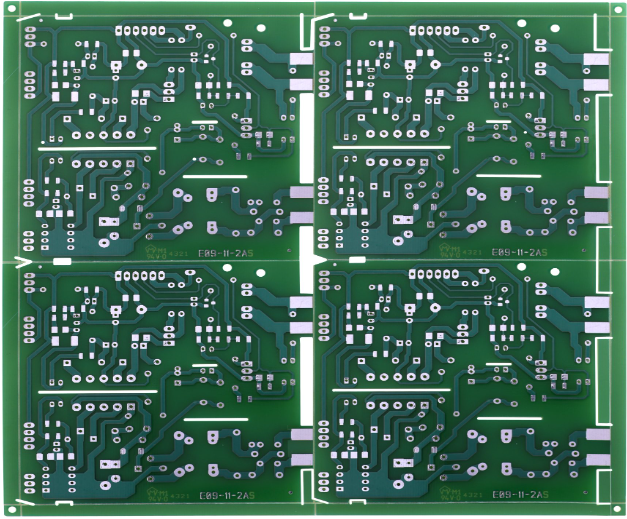

As the world becomes increasingly conscious of the environmental impact of industrial processes, the electronics industry, including Printed Circuit Board (PCB) manufacturing, is undergoing a paradigm shift towards sustainability. In this exploration, we will delve into the realm of sustainability in PCB manufacturing, with a specific focus on eco-friendly practices and the integration of green technologies. High-quality PCB boards are no longer just a technical requirement; they are also a symbol of responsible manufacturing in an era where environmental considerations play a pivotal role in decision-making.

-

Lead-Free Materials and RoHS Compliance

A cornerstone of sustainability in PCB manufacturing is the use of lead-free materials. The Restriction of Hazardous Substances (RoHS) directive has been a driving force in eliminating lead, mercury, cadmium, and other harmful substances from electronic components, including PCBs.

-

Environmental Impact: Lead is a hazardous material that poses significant risks to both human health and the environment. By adopting lead-free materials, PCB manufacturers contribute to reducing the environmental footprint of electronic devices.

-

Regulatory Compliance: RoHS compliance has become a standard in the industry. High-quality PCB boards are not only free from hazardous substances but also adhere to international standards, ensuring their acceptance in global markets.

-

-

Recyclable and Sustainable Materials

Sustainable sourcing of materials is gaining prominence in PCB manufacturing. Manufacturers are exploring recyclable and sustainable alternatives to traditional materials, aligning with the principles of the circular economy.

-

Recyclable PCBs: The use of materials that can be easily recycled at the end of a product's life cycle is a key focus. This includes exploring options for recyclable substrates and metals used in the PCB manufacturing process.

-

Bamboo and Bio-Resins: Some PCB manufacturers are experimenting with alternative materials such as bamboo and bio-resins. These materials are renewable and have a lower environmental impact compared to conventional options.

-

-

Energy-Efficient Manufacturing Processes

The energy-intensive nature of manufacturing processes is a significant consideration in the pursuit of sustainability. PCB manufacturers are adopting energy-efficient practices to minimize their carbon footprint.

-

Lean Manufacturing: Lean manufacturing principles, aimed at optimizing efficiency and reducing waste, contribute to energy conservation. Streamlining processes and minimizing unnecessary steps result in energy savings.

-

Renewable Energy Sources: Some PCB manufacturing facilities are transitioning to renewable energy sources, such as solar or wind power. This shift not only reduces reliance on non-renewable resources but also lowers the overall carbon emissions associated with production.

-

Energy-Efficient Equipment: Upgrading to energy-efficient machinery and equipment is a practical step towards sustainability. Modern, energy-efficient technologies contribute to reducing the overall energy consumption of PCB manufacturing processes.

-

-

Waste Reduction and Recycling Programs

PCB manufacturing inherently generates waste, but sustainable practices involve minimizing waste generation and implementing effective recycling programs.

-

Efficient Material Usage: Precision in material cutting and utilization minimizes offcuts and waste. Manufacturers are investing in technologies that optimize material usage, reducing the volume of discarded materials.

-

Closed-Loop Systems: Closed-loop recycling systems, where waste materials are collected, processed, and reintegrated into the manufacturing process, are becoming more prevalent. This minimizes the environmental impact of waste disposal.

-

E-Waste Management: Implementing responsible e-waste management programs ensures that end-of-life PCBs are properly recycled or disposed of, preventing the release of hazardous substances into the environment.

-

-

Green Technologies in PCB Manufacturing

The integration of green technologies is a key enabler of sustainability in PCB manufacturing. These technologies not only reduce environmental impact but also contribute to the production of high-quality PCB boards.

-

Water-Based Inks and Coatings: Traditional inks and coatings often contain volatile organic compounds (VOCs). Water-based alternatives eliminate or significantly reduce the use of harmful chemicals, enhancing the eco-friendliness of the manufacturing process.

-

Selective Soldering Techniques: Selective soldering, as opposed to wave soldering, allows for precise application of solder only where needed. This targeted approach reduces solder consumption and minimizes waste.

-

Green Chemistry in PCB Etching: The use of environmentally friendly etching solutions, often referred to as green chemistry, minimizes the environmental impact of the etching process, which is a crucial step in PCB manufacturing.

-

-

Environmental Certifications and Standards

Demonstrating a commitment to sustainability, many PCB manufacturers pursue environmental certifications and adhere to recognized standards.

-

ISO 14001 Certification: ISO 14001 is an international standard for environmental management systems. PCB manufacturers achieving this certification demonstrate their dedication to minimizing environmental impact and continual improvement.

-

EPEAT Certification: The Electronic Product Environmental Assessment Tool (EPEAT) certification evaluates the environmental performance of electronic products, including PCBs. Products meeting EPEAT criteria are recognized for their reduced environmental impact.

-

Carbon Footprint Measurement: Some PCB manufacturers actively measure and disclose their carbon footprint. This transparency allows customers to make informed choices based on the environmental impact of the products they source.

-

Summary

Sustainability in PCB manufacturing has evolved from being a niche concern to a fundamental aspect of responsible business practices. The integration of eco-friendly practices and green technologies by PCB suppliers contributes not only to a reduced environmental footprint but also to the production of high-quality PCB boards. As the electronics industry continues to advance, the synergy between sustainability and technological innovation will be paramount. Choosing high-quality PCB boards from suppliers committed to sustainability ensures that electronic devices not only meet performance standards but also align with the global imperative of environmental stewardship.